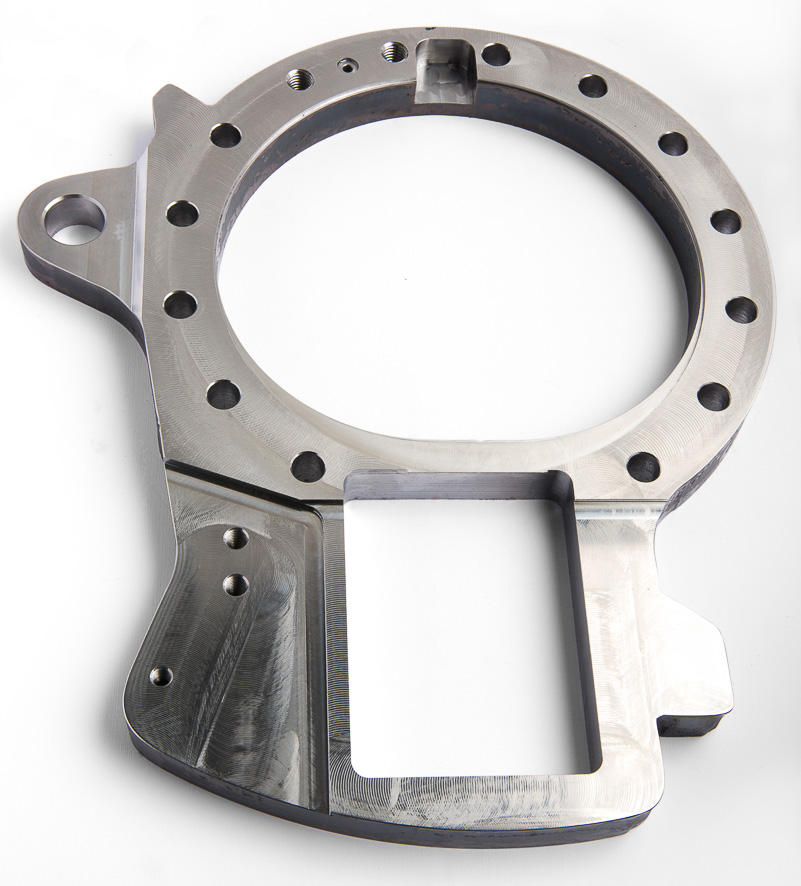

CNC Milling

With our vertical machining centre technology, our expert engineers can manufacture products or components to your precise specifications

Driven by integrated CAD/CAM software, our 4 & 5-axis mills are able to produce quality 2D or 3D components – with high speed 30-60 position automatic tool changers giving a powerful production capability.

Just about any material is workable, including Stainless Steel, Steel alloys, Aluminium, Brass, Copper and Plastics.

Extreme precision our specialty

We regularly assist manufacturers with products requiring extreme milling precision, to produce high quality, customised products to meet their needs.

Customised solutions

We are not afraid of difficult projects requiring an added level of specialist expertise and thinking outside the square.

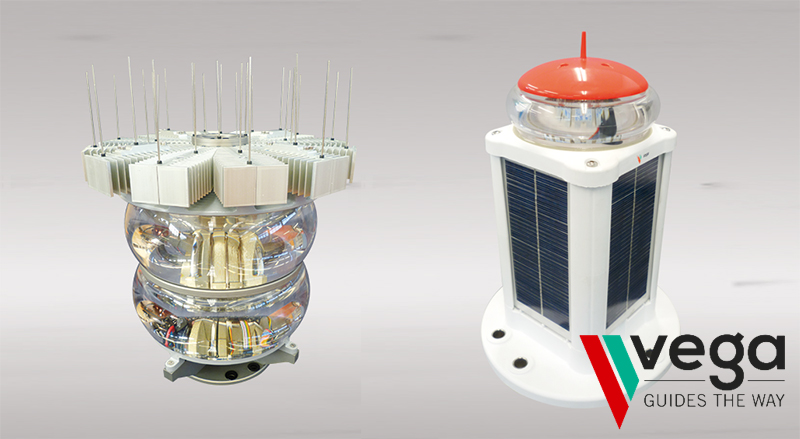

Relied on by worldwide manufacturers

Over the years we’ve worked with nearly ever sector including electrical distribution companies, power utility companies, rail, automotive, construction, mining, farming, the marine industry, and many more. Many leading companies rely on us to provide their products worldwide.

The best quality

Our design engineers begin by reviewing the product specifications provided from our client. We then source the best quality raw materials from within New Zealand. We have a fantastic network of steel and copper suppliers, which ensures we can source what is needed well within the required timeframe, even in cases where we are working to short deadlines.

CNC MILLING PLANT EQUIPMENT

Doosan DVF 5000 – 5 Axis

- Table size: 500 Dia x 400 h

- Tool Magazine capacity: 60

- 12,000 RPM – Direct Drive

- Laser Tool Measure

Doosan Mynx540 – 4 Axis

- Table size: 560 x 1,300mm

- Tool Magazine capacity: 30

- 8,000 RPM

Doosan 410 – 4 Axis

- Table Size 750 x 450mm

- Tool Magazine capacity: 30

- 20,000 RPM

ProtoTRAX SMX 3500

- Working Table size 900 x 400

- Tool Magazine capacity: 1

- 5,000 RPM

As part of the manufacturing process, we can take care of CNC machining, NC bending of copper, electroplating, anodising, certification, assembly and more.

Overflow assistance help when needed

A number of engineering companies regularly put their trust in us to help them meet fluctuating global demands for their product. We can take care of aspects of your manufacturing work, from small components to full product.

To reduce your workload, we can deal directly with your supplier and manage quality on your behalf. Let us help you improve efficiencies and outputs.

We value our strong customer relationships

We value good working relationships. Ongoing liaison is important to us. We ensure products leaving our factory are consistently the best quality and pride ourselves on providing a superior level of service.

As manufacturers ourselves, we know our customers are extremely busy, so you can even leave it to us to take care of scheduling debriefs and check-ins every couple of months.