Transport

With over 20 years of experience, Myriad Engineering is the first choice for many businesses in the transport sector when it comes to the fabrication or refurbishment of transport spare and replacement parts for rolling stock, buses, and coaches.

If you have an older fleet, or vehicles that were imported complete into New Zealand, then you probably have firsthand experience of the issues that come up when trying to source and replace parts and components. These can include:

- Obsolete parts that are no longer available

- Long lead times for the manufacturing or supply of parts from overseas

- Eye-watering prices, especially when international freight is involved

- Original designs or materials used leading to reduced component functionality or lifespan.

Machinery and tooling

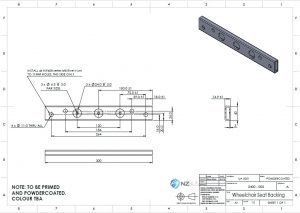

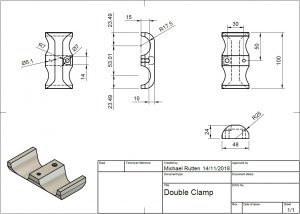

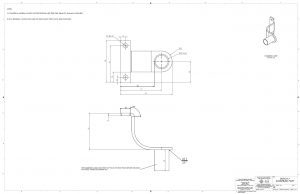

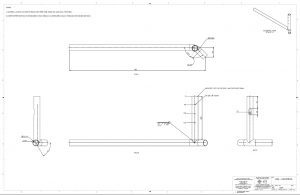

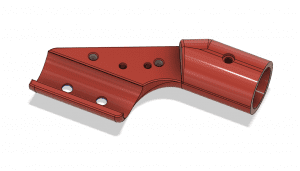

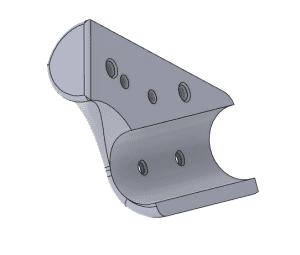

With significant investment in mill and lathe technology, our expert engineers can manufacture parts or components to your precise specifications. Driven by integrated CAD/CAM software, our 4 and 5-axis mills and 3 and 4-axis lathes can produce quality 2D or 3D components quickly and accurately

Just about any material is workable, including Stainless Steel, Steel alloys, Aluminium, Brass, Copper and Plastics.

If your spare parts or components need any welding, our welding robot offers several advantages over hand welding including increased productivity and improved accuracy. The consistent and repeatable product manufacture offered by a welding robot minimises wasted material and saves time and money.

From obsolete part to newly manufactured spares

With older vehicles, you often find that replacement parts are no longer being made or stocked. This can particularly be the case if coachwork or fit-out was done locally or in relatively small volumes.

In these cases, getting your existing parts refurbished, or having new parts fabricated for you can be the only solutions to keeping your vehicles or rolling stock going.

Made in NZ to reduce overseas lead times

If the parts you need have to come from overseas, then long lead times are not uncommon. This can happen with parts that are in-stock at an overseas supplier and need shipping but is inevitable if the parts are back-ordered and need to be manufactured overseas.

We work with you to plan how many of any part or replacement you need, and how often. If they are parts or components you need regularly, we can do larger manufacturing runs, which helps keep costs down, and then hold stock for you so you always know that there will be more available when you need them.

Cost effective parts manufacturing

Spare and replacement parts can often seem to be overly expensive, especially if you need a large number of parts for your vehicle fleet, or if the component wears quickly and needs replacing regularly.

If we make components for you, you pay the real cost of getting them made. You avoid the extra margins that grow with long supply chains and the profiteering that sometimes comes with the monopolies of factory spares.

Durable parts from high quality material

We often see parts and components of vehicles or rolling stock where the original design or the materials used result in functionality or durability issues that up costing operators more in the long run.

We have extensive experience when it comes to making spare and replacement that are better than the factory originals. We work with you to identify the issues and weaknesses of the original parts, then redesign them, often using more suitable longer lasting materials.[sp_wpcarousel id=””]